FTSE Russell Disclosure

Our Environmental, Social and Governance (ESG) practices are deeply integrated with our business growth strategy, driving us to enhance operational sustainability, reduce our carbon footprint and innovate for a greener future. By aligning business growth with ESG priorities, we are not only strengthening our resilience but also contributing meaningfully to the global climate agenda.

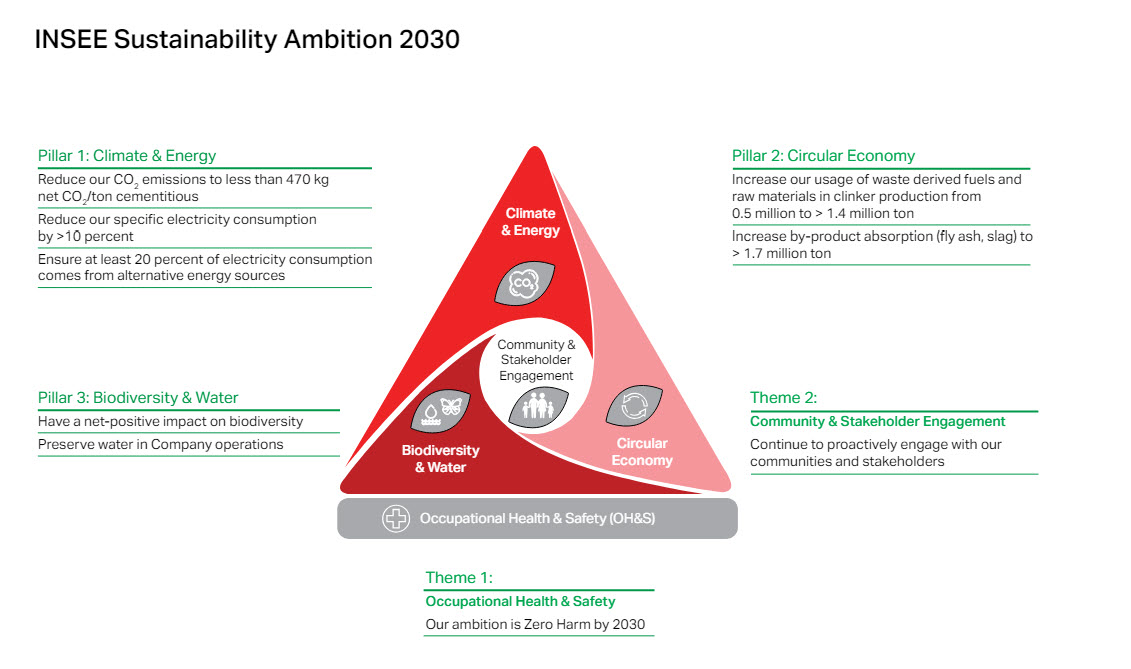

SCCC Group has devised the Sustainability Ambition 2030, in which Thailand Cement Business has shared the same ambition. However, we develop our ambitious targets based on business operations in Thailand, in alignment with all business units across the Group, to ensure that as a Group, we can really make positive impacts to the environment.

Environmental

Climate & Energy

In this context INSEE Group has reviewed its Scope 1 roadmap ambition: from 530 kg Net CO2/ton cementitious materials originally defined to 470 kg Net CO2/ton cementitious by year 2030. This represents a reduction of 25 percent compared to 2020 reference year. This 2030 target is consistent with a pathway to 1.5 degrees by 2050 following the EIA (International Energy Agency) reports.

To achieve this ambition there are necessary key focus areas for INSEE Group as follows,

- Further advances in our low carbon cement portfolio.

- The deployment of alternative energy sources, thermal and electrical.

- Ongoing efficiency improvements to strengthen the baseline and to reduce wasted energy along the production processes.

- Awareness and implantation of selected new technologies to support this ambition.

The Group has implemented various projects and measures to continuously reduce greenhouse gas emissions. These include thermal energy projects, which increase the Thermal Substitution Rate (TSR) through greater use of Alternative Fuels (AF) to replace coal, and electrical energy projects, such as the development of solar energy initiatives. In addition, the Group has developed and commercialized low-carbon cement products, driving progress toward sustainable growth.

For more information on key projects during the past year, please refer to the 56-1 One Report, section Sustainable Development, or visit the Company’s website under Environmental Management at https://siamcitycement.com/en/esg/-e-environmental

Management of Air Quality

The Group recognizes the importance of controlling and reducing air emissions that may impact the health of employees, nearby communities, and the environment. Accordingly, the Group has developed a Proactive Air Quality Management Plan covering both plant areas and surrounding communities to enhance air quality management beyond regulatory requirements.

Under this plan, the Group has implemented key measures as follows:

- Control and reduction of air emissions from plants that use waste as alternative fuel or raw materials, ensuring that emission levels remain within stringent standards.

- Installation of high-efficiency dust control systems, such as Bag House filters and Electrostatic Precipitators (ESP), to capture particulate matter before release into the atmosphere.

- Installation of Continuous Emission Monitoring Systems (CEMS) to continuously monitor air emissions and ensure the optimal performance of dust control systems.

- Application of the “Mitigation Hierarchy” principle in air quality management strategies to minimize pollution risks and promote the adoption of cleaner technologies.

- Collaboration with key stakeholders, including government agencies, local communities, and private organizations, to jointly address environmental issues and promote sustainable development.

These initiatives represent the Group’s process-based targets to continuously reduce and prevent air pollution by enhancing technology, operational efficiency, and stakeholder engagement toward sustainable outcomes.

The Group emphasizes collaboration with government agencies and business partners to achieve sustainable environmental management. This includes cooperation with the Ministry of Industry to comply with environmental standards under the Notification on Standards for Air Emissions from Cement Plants Using Waste as Fuel or Raw Materials, B.E. 2549 (2006), and collaboration with affiliated companies in waste management by using waste as alternative fuel and raw materials in cement production. These efforts help reduce fossil fuel and natural resource consumption, lower air emissions, and support the transition toward a Circular Economy.

To support the Group’s commitment to sustainable environmental management, the Group has adopted the ISO 14001 Environmental Management System, an internationally recognized standard for managing and controlling environmental performance across all operations. The certification is granted by accredited independent certification bodies such as SOCOTEC Certification UK Ltd, Intertek Certification Limited, and Management System Certification Institute (Thailand). Currently, approximately 83% of the Group’s subsidiaries and operational units have been certified under ISO 14001, while the remaining sites are in the process of obtaining certification. This reflects the Group’s goal of establishing a unified environmental management system across all operations.

In addition, the Group has continuously allocated budgets for pollution control and air emission management, covering the installation and maintenance of pollution control systems (Bag House, ESP, and CEMS), as well as expenses for air quality monitoring, regulatory reporting, and energy used in pollution control operations. In addition, the Group continues to invest in innovation and research & development (R&D) to enhance pollution control efficiency and optimize resource use. Examples include developing technologies to utilize waste as alternative fuel and raw materials, supporting sustainable production and environmentally friendly operations in line with the Sustainable Development Goals.

Continuous monitoring of air emissions through CEMS shows that all pollutant concentrations remain within the regulatory limits, including: Total Suspended Particulates (TSP) ≤ 50 mg/m³, Sulfur Dioxide (SO₂) ≤ 30 ppm, Nitrogen Oxides (NOₓ) ≤ 500 ppm, Heavy metals: Mercury (Hg) ≤ 0.1 mg/m³; Cadmium and Lead (Cd + Pb) combined ≤ 0.2 mg/m³; and other heavy metals combined ≤ 1 mg/m³ etc.

These results demonstrate the Group’s progress in achieving its process-based targets and commitment to maintaining emissions within the required standards. Further details on the environmental performance are available in the https://investor.siamcitycement.com/storage/content/sustainable/sccc-sd-index-2024-en.pdf

Circular Economy

SCCC Group is driving circularity across our value chain to achieve operational decarbonization goals. By minimizing construction waste and extending the lifespan of buildings and infrastructure, we deliver innovative, sustainable solutions through our Green Portfolio, including hydraulic cement with reduced clinker content as an eco-friendly alternative to traditional portland cement.

One of the key actions driving circularity within our value chain is led by INSEE Ecocycle, a subsidiary specializing in waste management solutions. Since 2001, INSEE Ecocycle has been transforming waste into valuable resources through co-processing in cement kilns, eliminating waste without harmful emissions, reducing reliance on fossil fuels and minimizing environmental impact. Collaborating with government bodies and industries, INSEE Ecocycle sets benchmarks in hazardous waste management while aligning with the Sustainable Development Goals, focusing on climate action and circular resource use.

our commitment to circularity extends to efficient waste management through consistent production process improvements, optimizing the value of resources while reducing the need for raw material extraction. By utilizing by-products from various industries, we substitute finite natural resources and fossil fuels in cement production. This approach not only conserves resources but also addresses critical waste disposal challenges, further reinforcing our dedication to sustainable development and resource efficiency.

By 2030, our ambitious Circular Economy targets, we aim to increase the use of waste-derived fuels and raw materials in clinker production from 0.5 million tons to over 1.4 million tons. Additionally, we plan to boost by-product utilization such as fly ash and slag by 65 percent, reaching over 1.7 million tons annually to produce cementitious products.

- Our circularity strategy is built on reducing the reliance on primary raw materials and enhancing the longevity of structures built with our products. We are committed to promoting sustainability through the following key initiatives:

- Promoting Circular Products and Alternative Fuels: We focus on increasing the use of alternative fuels and incorporating circular products in our operations. This includes efforts to meet our thermal substitution and clinker factor targets, thereby reducing the consumption of virgin raw materials.

- Reducing Carbon Footprint: Through initiatives such as adopting hydraulic cement and closing the carbon loop, we aim to significantly lower our carbon emissions. These steps are part of our broader commitment to mitigating climate change and advancing sustainable construction practices.

- Partnerships in Construction and Demolition Waste Management: We are exploring partnerships across Southeast Asia to manage construction and demolition waste more effectively, ensuring that these materials are repurposed and reused in a circular economy framework.

Management of Waste

Human activities create approximately 2,000 million tons of waste annually, which adversely affects the environment and contaminate various ecosystems. 31% of waste disposal is done by landfill, which habors the risk of a variety of waste contaminating groundwater in an around the area. 20% of methane emission is also found in open landfill areas. The Group is committed to completely avoid using landfill for disposal and reduce the volume of solid waste gradually, aiming for Zero Landfill. We also embrace the concept of circular economy to reduce total waste, aiming to reduce waste from the sources. In addition, to guarantee no landfill disposal, we adopt an advanced recycling system, which greatly reduce the amount of waste that requires disposal. One of our Group Companies, INSEE Ecocycle Limited, has operated with the concept of circular economy built into its business chain, offering waste management solution wherein waste is turned into a valuable resource through treatment in the cement kilns, which dosposes of waste without resulting in pollutants, reduce reliance on fossil fuel, and minimize environmental impact. The Company also collaborates with the public sector agencies and other industrial sector organizations to formulate a hazardous waste management standard, and has operated in full alignment with our sustanability targets, particularly meeting the challenges of climate change, and effective usage of circular resources.

Using industrial byproducts in place of natural resources and fossil fuel in cement production not only helps with conserving limited natural resources, but also helps with waste disposal concerns. The Group has set the target to increase usage of fuel from waste and material from waste in clinker production, increasing from 0.5 million ton to over 1.4 million ton annually. Concurrently, plan to increase usage of byproducts such as fly ashes and slags by 65% or over 1.7 million ton annually in cement adhesive by the year 2030. These strategies reflect our committment to reduce any impact to the environment, promote circular economy, and improve the efficiency of resource usage in a responsible manner in the cement industry, such that the industry is further driven towards environment friendliness and long term sustainability.

Waste Generation

| Detail | Unit | Year | ||

|---|---|---|---|---|

| 2022 | 2023 | 2024 | ||

| Total waste* | Kilograms | 32,539,110.50 | 94,901,345.11 | 67,132,033.28 |

| Total Non-hazardous waste | Kilograms | 30,827,170.10 | 75,026,686.89 | 45,694,096.50 |

| Garbage and non-hazardous waste - Landfill | Kilograms | - | ||

| Garbage and non-hazardous waste - Incineration with energy recovery | Kilograms | 37,792,192.40 | ||

| Garbage and non-hazardous waste - Incineration without energy recovery | Kilograms | 69,860.00 | ||

| Garbage and non-hazardous waste - other | Kilograms | 7,832,044.10 | ||

| Total Hazardous waste | Kilograms | 1,711,940.40 | 19,874,658.22 | 21,437,936.78 |

| Garbage and hazardous waste - Landfill | Kilograms | - | - | |

| Garbage and hazardous waste - Incineration with energy recovery | Kilograms | 19,664,055.00 | ||

| Garbage and hazardous waste - Incineration without energy recovery | Kilograms | 1,236,716.00 | ||

| Garbage and hazardous waste - other | Kilograms | 537,165.78 | ||

| Total Reused/Recycled Waste | Kilograms | 31,032,034.90 | 38,968,552.10 | 12,214,406.30 |

| Reused/Recycled non-hazardous waste | Kilograms | 30,757,904.90 | 38,800,262.10 | 11,310,834.30 |

| Non-hazardous waste and materials reused (Reuse) | Kilograms | |||

| Non-hazardous waste and materials reused (Recycle) | Kilograms | |||

| Reused/Recycled hazardous waste | Kilograms | 274,130.00 | 168,290.00 | 903,572.00 |

| Hazardous waste and materials reused (Reuse) | Kilograms | 528,082.00 | ||

| Hazardous waste and materials reused (Recycle) | Kilograms | 375,490.00 | ||

| Total Non - Reused/Recycled Waste** | Kilograms | 1,507,075.60 | 55,932,793.01 | 54,917,626.98 |

Remark: Further, the Company disclosed its waste and waste volume data (according to the Stock Exchange of Thailand’s ESG Data). The disclosed information covers the Group's cement segment, both domestic and international, which includes Siam City Cement Public Company Limited (including head office), Siam City Cement (Vietnam) Company Limited, Siam City Cement (Bangladesh) Company Limited, and Siam City Cement (Lanka) Company Limited, as well as the Group's waste heat power generation business through Siam City Power Company Limited.

(*) Exclude the total weight of waste generated outside of the Company, which is not responsible for the waste disposal or treatment cost.

(**) Non-Reused/Recycled Waste is calculated as Total Waste – Total Reused/Recycled Waste. This waste is disposed of through Incineration with energy recovery, Incineration without energy recovery, and Other methods.

Approach to Waste Management

We are aware of the adverse effects waste has on the environment, and so the Group is committed to using resources efficiently and reducing waste resultant of the production processes. Our approach sees reduction of the primary resources used in production, while also minimizing impact to the environment and reducing waste disposal cost. Waste volume is consistently tracked and waste is catogorized and managed systematically. We promote usage of circular economy in the production processes to address the issues of waste in a sustainable manner, adopting the waste management hierarchy with special emphasis on waste prevention, reduction, reuse, recycling, and processing into energy source.

Important Projects

- Driving circular economy though collaboration with business allies: The Group collaborates with government agencies, education institutes, and allies in the private sector to initiate and operate many important projects including the material return spots including one-use plastic and underwear, and landfill mining project to separate valuable resources from waste. These projects are aligned with the Company’s committment to support our allies in the matter of sustainability through reduction of waste.

- Industrial cleaning service throughsustainable innovations: The Group collaborates with other leaders of the industry to support the sustainability goal and driving of circular economy of said allies. Our innovations and solutions offered emphasize reduction of impact to the environment alongside improved efficiency and operation safety.

More information on the Group’s circular economy can be found in: https://sccc.listedcompany.com/misc/one-report/2024/20250325-sccc-form-561-2024-en.pdf

Biodiversity and Water

The Group recognizes that natural resources, such as biodiversity and water, are fundamental to ecosystems and serve as essential resources supporting the Company’s operations. This is particularly relevant to the cement manufacturing industry, which relies on the responsible use of natural resources. Therefore, sustainable management of these resources is considered a key business strategy of the Group.

Under this responsible operating approach, the Group has established clear measures and targets to minimize environmental impacts, restore ecosystems, and use water resources efficiently. The Group strives to create a balance between economic growth and environmental conservation, ensuring long-term benefits for the business, communities, and nature.

Protection and Restoration of Water Resources

The Company sees the significance of biodiversity and water resources management. Water is a vital resource for development and is crucial in supporting biodiversity and human life. Unfortunately, it is plagued with issues of scarcity, which lead to biodiversity loss and negatively impact nutrient cycles within soils, plant life and essential food crops. These issues are interconnected and will assist in handling land erosion and the regulation of the quality and quantity of water. The conservation of water and biodiversity cannot be neglected. Therefore, we must adopt and emphasize best practices. Sustainable Development Goal (SDG) 17 proposed by the United Nations (UN) urges collective action toward ensuring clean water and sanitation security for all.

SCCC Group is committed to reducing specific water consumption by over 20 percent and increasing the use of surface water collection to over 45 percent by 2030, Using a water resources management scheme that is focused on efficiency, the Group has worked to reduce unnecessasry use of water during production processes. We are also constantly looking for new ways to manage water usage even more effectively and efficiently.

| Detail | Unit | Year 2020 Baseline | 2024 Performance | 2030 Target |

|---|---|---|---|---|

| Water Consumption | l/ton cem | 301 | 245 | 240 |

| Surface Water Usage | % | 32 | 37.5 | 45 |

Remarks: The disclosed information includes the Group's cement segment, domestic and international, which includes Siam City Cement Public Company Limited, Siam City Cement (Vietnam) Limited, Siam City Cement (Bangladesh) Limited, and Siam City Cement (Lanka) Limited, and the waste heat power generation business which includes Siam City Power Company Limited. Including the joint venture company, Chip Mong Insee Cement Corporation.

Approaches to Water Resources Management

The Group is acutely aware of the importance of water resources, expecially amidst the ongoing climate challenges. Each site has a water action plan. Among site specific actions, it consists of more general initiatives such as systematic measurement of our water consumption to ensure water conservation. To identify and track potential water loss as well as opportunities to optimize water consumption such as increasing equipment cooling efficiency, regular water balances are conducted by using the GCCA guideline and tools. Moreover, we keep collecting surface water by building more reservoirs (ponds and quarry dewatering) to ensure sufficient water supply for continuous operation. This also serves to maintain and reduce usage of groundwater, which is in line with the Group’s 2030 Sustainability Ambition.

The Company has appointed a Water Management Committee to oversee, supervise, and drive the implementation of water management activities at Saraburi operations. The Water Management Commitee’s responsibilities include the below processes:

- Review and develop a Water Diagram.

- Inspect and analyze the Water Balance.

- Survey water meters and pipelines, and compile a Water Meter List.

- Verify the accuracy of water meters and update relevant records.

- Test and validate meter functionality, and repair or replace faulty meters.

- Identify water leakage points and develop maintenance plans for critical areas.

The above are regularly analyzed for continuous improvement of water management enhancement plans, and are part of the push towards introduction of processes that promote recycling and usage reduction of groundwater. These work processes are consistently monitored and improved upon, to guarantee alignment with our sustainability goals.

The Company’s focus is on environmentally responsible operation, and to this end we operate in strict compliance with the relevant laws and water quality standards. Wastewater treatment systems are regularly inspected, as is the quality of wastewater output by such systems, to ensure they meet global standards. All business units of the Group are in complete alignment with the Sustainability Guidelines of the Global Cement and Concrete Association: GCCA,) with water usage regularly tracked and water usage reports covering key indicators in a consistent manner. In particular, water usage for our operation in Saraburi is independently monitored and verified by Kasetsart University through the carbon footprint assessment process as dictated by the regulations for ready-mix cement products of the Thailand Greenhouse Gas Management Organization (Public Organization.)

You can find more details on water-related operations in the SD Performance Index 2024 https://siamcitycement.com/en/esg/-esg-publications and ESG Data Report https://investor.siamcitycement.com/storage/content/downloads/one-report/2024/20250502-sccc-esg-2024-en.pdf

Important Projects

The Group is well aware of the importance of efficient and sustainable water resources management to prepare for water quality and climate challenges in various areas, which can directly affect operation costs. The Group, as such, has adopted a systematic water risk assessment and management scheme, which tracks all relevant costs, such as expenses for reserve water procurement, water treatment, reservoir maintenance, and compliance to relevant laws and regulations. The Group has worked towards reducing water risks and enhancing long term water flexibility through investment in various water management systems, such as the water metering system improvement project for improved accuracy and eficiency in assessing water usage, the waste heat recovery (WHR) water recycling system, and retention and usage of rainwater in production processes.

- Water metering system improvement – The Group has invested in improving the water metering system, adopting the variable speed drive (VSD) for improved water circulation and reduced leakage. A smartphone application has also been developed for water meter recording, which helps with accurate tracking of water usage and ease of use. This allows for systematic, efficient water resources usage tracking with high accuracy.

- Plant water leakage monitoring project – The Group has initiated an ongoing activity to detect water leakage in plants, with all employees and contractors welcome to participate in inspecting and reporting leakages in operation areas, to encourage timely reporting of malunctions and swift addressing of such, while also encouraging efficient use of water resources and operation cost reduction. The activity covers the cement business of the Group, both domestic and overseas.

- Ground water reservoirs - The Group has constructed two reservoirs for surface water reserving various areas, including 2 reservoirs in Saraburi, one being an open pit with a capacity of 200,000cbm, and another a P8 reservoir with a capacity of 25,000cbm. Two reservoirs are in Vietnam, one in the Cat Lai Port area, and one in the Hiep Phuoc plant area. One reservoir is in Sri Lanka, being located in the Puttalam plant area. Surface water in said reservoirs are used in pollution control processes as well as temperature control during production, which aligns with out goal to reduce reliance on groundwater, per our 2030 Sustainability Ambition, which aims to use surface water for as much as more than 45% of the processes.

- Zero Discharge project – The Group prioritizes comprehensive wastewater management, with water used in production processes within the Company’s operation area being treated before being reused in entirety, resulting in zero wastewater reaching external water reserves. For our operation in Vietnam, the waste heat receovery (WHR) system is used in the Hon Chong plant, with 10,000cbm – 15,000cbm of wastewater being treated and reused annually. Such water is also used, after treatment, in the Hon Chong plant, and the Cat Lai port as part of the operation of the Company’s other businesses.

Biodiversity Disclosure Scope of the Group

Disclosure of information pertaining to biodiversity, as well as the use of “the Group” in this context, cover only Group Companies that deal in the cement production business, which operates mines as part of the production processes. This include such Group Companies in Thailand, Vietnam, and Sri Lanka, excluding a Group Company Bangladesh which only operates a cement production plant.

Biodiversity Strategic Missions and Target Setting for Group Sustainability

The Board of Directors fully respects the natural capital, which is critical to doing business in a sustainable manner, and sees the importance of monitoring and tracking operations of all levels to ensure, with strategies in place to promote the achievement of such a goal, the Group’s business operations are truly environmentally and socially responsible.

In 2020, the Board of Directors considered and approved 5 sustainability targets of the Group, with “Biodiversity and the Significance of Water” being one of such targets. As well, the Board of Directors approved the adoption of relevant Key Performance Indicators (KPI) including net positive impact to biodiversity within 2030 with the baseline year being 2020, with all businesses in all countries that operate mines being mutually responsible for this KPI.

Our Domestic and International Allies

In all countries where the Group operates mines, environmental impact assessment reports (EIA) are conducted for new projects as part of the application for concession, and for existing projects as well for renewal of concessions. These reports include considerarion of biodiversity matters jointly assessed by private and public sector experts. During operation, we collaborate with academics from leading universities on environmental subjects to conduct biodiversity self evaluations and biodiversity audits to ensure our operation plan is continuously improved

On the international scale, Siam City Cement Public Company Limited is a member of the Global Cement and Concrete Association (GCCA) whose objective is to elevate the cement and concrete businesses. We collaborate with GCCA members, who are leading cement producers around the globe, in designing biodiversity targets for net positive impact. The Group also co-signed a memorandum of understanding with the International Union for Conservation of Nature and Natural Resources (IUCN) in 2021, which dictates the implementation of roadmaps to support the countries in developing biodiversity action plans.

These actions reflect the Group’s resolve to leave positive impacts biodiversity-wise to the areas we operate in, in tandem with improving the quality of the environment, addressing local communities’ needs, and meeting the expectations of all stakeholders. Utmost care is given to all parts of our operation, with plans in place to prevent and reduce the impact to, and to restore, maintain, and promote biodiversity in the operation areas and surrounding areas.

Assessment of Critical Habitats and Biodiversity Risk Management

To prepare reports on the environmental impacts by mining, government registered experts are fully involved in data collection and field survey. Collected data include species of plants and animals found in the project areas, and the coverage of assessments include the assessment on potential impact to the environment and wildlife in the operation areas during the projected operation timeline in financial terms. As well, measures to reduce, control, and prevent potential impact are reviewed by government agencies.

Environmental impact assessment reports are a requirement for all new mining concession proposals and concession renewal applications, and as such the Group is proactively conducting annual self-assessments jointly with associated academics, with external experts employed to conduct perdiodical reviews, to ensure measures according to the restoration work plan are executed efficiently and that appropriate improvements are made where needed.

Our mining operations are mountaintop mining, which requires only deforestation of the operation areas and utility areas at the centre of the operation areas, with surrounding areas being excluded, to act as buffers and to reduce environmental impact. Continued mining operations will only see the same operation areas being slightly expanded. Our mining operations are accompanied by the area restoration plan, which aims to rehabilitate the affected areas and restore them to as close to their natural state as possible. Limestone mines in Thailand are located in Saraburi, in mountainous areas, covered in mixed deciduous forests, with buffer zones surround the mines nearly as large as the mining areas themselves.

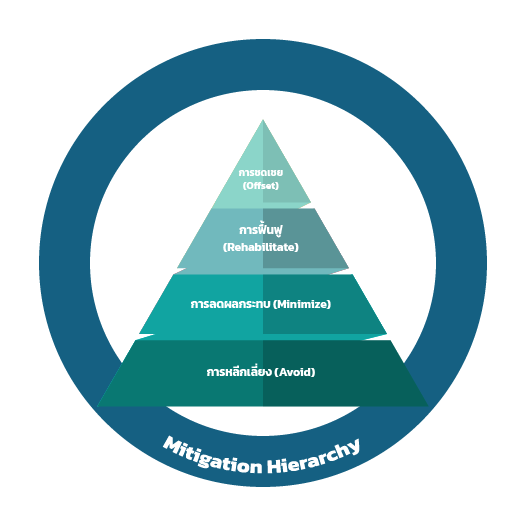

The Group manages biodiversity risks systematically as dictated by our migitation hierarchy, as shown below.

The Mitigation Hierarchy

Examples of Mitigation Hierarchy, Targets, and Annual Results

Avoid : We set a target for deforestation prevention in the buffer areas, aiming for zero deforestation. In 2024, this target was met at 100% success rate.

Minimize : We set a target for all mining operations to be conducted only in the pit areas, and to comply strictly to the mining area plans, with expectation being 100% compliance. This was fully achieved in 2024.

Rehabilitate : We set a target for restoration of mining operation areas after their operations have concluded as determined in the EIA. For example, in Thailand, we aim for an annual 5.875 rais of area restoration. For 2024, we exceeded this target, with 377 rais of area being restored, 32,646 tree planted, and 40 species of seedlings being planted. As well, our target for extermination of white lead trees, an invasive species, to preserve other species in the target areas, was exceeoded in 2024. Our obligations to IUCN set to be met within 2025, as well, were all met in 2024.

Offset : We collaborate with the communities, related government agencies, and the IUCN and other such similar organizations in the forestation of areas surround our plants, as well as in other plant and wildlife preservation projects. As an example, in Sri Lanka, the Group has initiated a project to restore mangrove forests negatively impacted by fishery and tourism. As part of the project, in collaboration with the Wildlife and Ocean Resource Conservation (WORC,) the Group has planted 1,500 mangrove trees, and 1,500 other plants around the Thalathuduwa and Kurulu Duwa islands, with the outcome of this project continuing to be tracked by WORC. Another example is the restoration project for coral reefs adversely affected by the En-nino effect, which sees the surface temperature of the Central Pacific Ocean and the near-equator area of the Eastern Pacific Ocean rising to an abnormal degree, with the project aiming to create an infrastructure for coral and species of fish’s habitation and reproduction. The project is currently under monitoring by the Sri Lanka Navy and the IUCN. Another example in Vietnam is our sarus cranes conservation program in the Binh Tri and Phu My areas.

(Details of our Sri Lanka and Vietnam subsidiaries’ collaboration with IUCN can be found in the below links)

https://iucn.org/story/202212/iucn-sri-lanka-teams-insee-another-three-years-ensure-nbs-development

Examples of Mitigation Activities in Thailand in 2024

- The mining area restoration fund – The Group fully supports the restoration of operation areas after mining is concluded, annual mining and restoration plan available, prepared in collaboration with experts from Kasetsart University with extensive and ongoing surveying and research in the areas’ biodiversity to ensure the areas are restored to as close to their natural state as possible. Data of wildlife and plant species is collected and analyze, acting as a base of scientific information for which we use in managing the restoration areas. The Company also tracks the growth of planted trees as part of this project, to assess the effectiveness of the restoration. The data we collect is used for habitat restoration, preservation of plants and wildlife, and ecosystem preservation. The result of this project not only helps with more effectively restoring the areas, but also reflects the Company’s progress in creating a positive impact towards biodiversity, and our commitment to achieve net positive impact by the year 2030.

- Seedlings project – The Group has surveyed the buffer areas and has found that there are more than 100 local species of plants in such areas. We have gather seedlings of the local species from these areas for propagation in the established plant nursery, which are then ised as part of the conservation and restoration of loca plants in the areas to return them to as close to their natural state as possible. The resultant plant seedlings from the nursery are also used in other coporate social responsibility programs with communities surrounding the areas. The Company’s target is to propagate at least 50 species of local plants by the year 2030. In 2024, over 40 species of local plants have been propagated. The Company also consistently minitors and controls invasive species of plants found in the areas, to ensure they are contained and their impact to biodiversity is minimized.

Examples of local plants in the plant nursery

Common name Capparaceae

Scientific name Maerua siamensis (Kurz) Pax

Common name Masang

Scientific name Mudhuca pierrei (William) H.J. Lam

Common name Bauhinia

Scientific name Bauhinia variegata L.

Common name Caesalpinia sappan L.

Scientific name Caesalpinia sappan L.

Common name False lime

Scientific name Suregada multiflorum (A. Juss.) Baill.

- Give & Grow project – The Group collaborates with the relevant government agencies and organizations for the offsite tree-planting initiative, which is aimed at restoring the ecosystem and promote diversity on a wide scale. The Company provides seedlings from the Company’s nursery to said agencies and organizations both national and local for planting and restoring areas, with the target being 500 seedlings provided annually. In 2024, the Company provide more than 900 seedlings, with collaborations being made with the Navaminda Kasatriyadhiraj Royal Air Force Academy, the Chet Kot-Pong Kon Sao National Park, and local communities in the Thap Kwang subdistrict, Kaeng Khoi district, Saraburi. This coordinated effort with the agencies and local communities reflects our role in being a driving force behind the conservation of natural resources and lessening of the negative impact to biodiversity, which pave way to sustainability for the communities and the country.

- The seedlings for communities and schools project – The Group promotes participations in conservation and restoration of biodiversity in the operation areas by the local communities and schools through the communities and schools seedlings project, an activity which sees a total of 800 seedlings being planted annually. The project encourages participation and building the sense of community pride in the people of the communities and the local students, as drivers of the restoration and sustainable conservation of the ecosystem.

- Communities seedlings – The Group buys seeds from the local communities which are then nursed into seedlings for use in restoring the mining areas. This provide the communities with additional income, and involves the communities directly in the sonservation and restoration of natural resources.

- Schools seedlings – The Group provide small seedlings from the nursery to local schools, such as the Thap Kwang Kindergarten, and encourages students to care for and learn about the plants and conservation of nature. Grown seedlings are collected by the Company for further use in mining areas restoration.

- Stakeholders knowledge sharing – The ecology classroom activity is created to provide knowledge and information on biodiversity in the Saraburi quarry and the surrounding areas. An Open House activity is also arranged for the local communities and schools, to promote the awareness of and participation in conserving biodiversity and community participation.

Social

Human Rights Disclosure Statement of SCCC Group

At INSEE, we are committed to upholding human rights principles across all our operations. Setting the standards for the built industry of tomorrow, we prohibit discrimination, ensure fair treatment of employees, and expect the same from our business partners. We engage transparently with communities and customers, continuously improving our human rights practices to create a sustainable future for all our stakeholders.

Human Rights Care

The Group has communicated the expectation and preferred practice pertaining to human rights matters to all stakeholders including employees, suppliers, contractors, and business allies, through various media such as the Code of Conduct, the Sustainable Development Policy which covers human rights matters, and the Responsible Procurement Policy, or the Supplier Code of Conduct and Privacy Policy for Suppliers This is also reflected in our selection and assessment processes of existing and potential suppliers, which are designed to be fair and transparent, ensuring that all parties understand and are able to adhere to the principles of human rights appropriately.

The Group sees the importance of respecting to and promoting human rights, and is dedicated to ensuring fair treatments to all with no discrimination. Consequential of this, the Company has made human rights matters a significant part of the Business Code of Conduct. Employees are required to undergo training courses on the Business Code of Conduct, which are scheduled regularly, to ensure employees' awareness and deep understanding of adherence to human rights, and to ensure no violation of human rights occurs in any work process.

The Company places great importance on creating a safe, respectful, and harassment-free working environment to promote a friendly and fair workplace atmosphere for all employees. The Head of Legal, who also serves as a member of the Screening Committee for cases reported through the INSEE Speak Up whistleblowing channel, plays a key role in ensuring the Company’s compliance with laws, regulations, and the Code of Business Conduct. This role includes providing legal advice and managing sensitive cases involving bullying, harassment, or other inappropriate workplace behavior, and it requires strong expertise in labor law, human rights, and internal grievance management.

Under the Company’s Whistleblowing Policy, any incident or complaint reported through INSEE Speak Up must be reviewed by the Screening Committee. The Committee is responsible for conducting a thorough, impartial, and confidential investigation, and for recommending appropriate corrective and preventive actions to management. The Company is committed to fostering an organizational culture of mutual respect, free from discrimination, bullying, and harassment of any kind, to ensure that all employees are treated equally and with dignity in the workplace.

Community and Stakeholder Engagement

INSEE’s ambition is to proactively engage with its communities and stakeholders.

Community Caring

The SCCC Group ensures sustainable community growth by developing annual engagement plans for each business unit. These plans integrate Corporate Social Responsibility (CSR) initiatives during and after business operations, fostering open communication with local communities. By encouraging active participation in planning and executing development activities and leveraging the Group’s expertise and resources, these initiatives contribute to the long-term development of both communities and society.

One of the important activities is the Evening Visit Project, a long running activity aimed at aligning building trust between the Company and the communities surrounding the operation areas. The project sees monthly visits to the communities surrounding the Muak Lek and Kaeng Khoi being conducted by the Company-assigned working group, who receives feedbacks, provides counsel, collects suggestions and grievances relating to the operation of the Company, and exchange information relating to measures for environment preservation, safety, and community development, to encourage the communities to participate constructively.

This activity is tracked through systematically prepared and kept minutes, which also include the Action Log for tracking and reporting topics in subsequent visits. Focus is on issues or concerns from the communities that are tangible and verifiable. For the sake of efficiency, the Company assigns representatives from the Community Relations Department, who will responsible for this activity, with roles and responsibilities clearly defined, and resources clearly allocated, to ensure that the activity achieves its objectives and is truly beneficial to the communities.

In addition, the Company puts emphasis on two-way communication, which allows the communities to voice their opinions or concerns directly, and to collaborate with the Company in planning social responsibility activities, such as development of green space, vocational promotion, education support, and environmental preservation activities, which not only elevates the quality of life on the communities, but also serves to strengthen the relationship between the communities and the Company.

You may find more information about the company’s key activities in the Annual Report (Form 56-1 One Report), under the section Sustainability Development, or on the company’s website under the menu Social Engagement at https://www.siamcitycement.com/en/esg/-s-social.

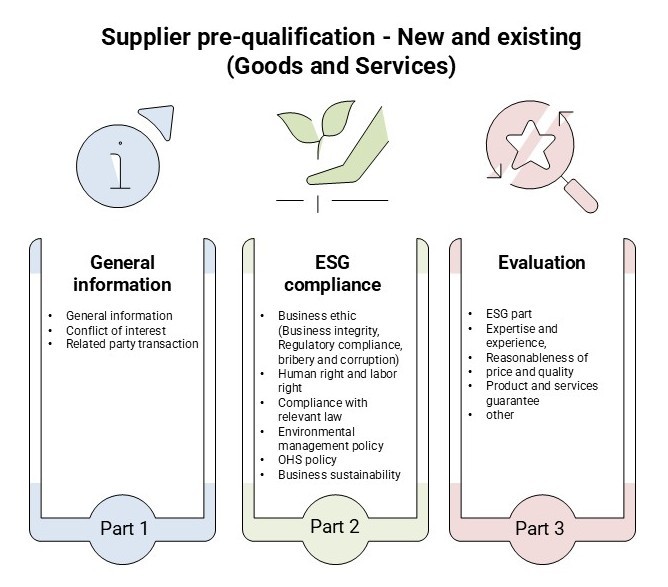

Sustainable Supplier Management and Development

The Group values its suppliers as strategic business partners who play a vital role in the Company’s success. Building long-term and sustainable relationships with suppliers is a key driver for business continuity and shared value creation for all stakeholders. The Group is therefore committed to managing and developing its suppliers systematically under the principles of good governance, transparency, and sustainability (ESG). This approach ensures that all suppliers conduct their business responsibly with respect for the environment, society, and corporate governance, while continuously enhancing operational standards to achieve mutual and sustainable growth.

At the same time, the Group recognizes that effective supply chain management at every stage—from raw material sourcing and production to the delivery of products and services—is essential to strengthening partnerships with suppliers. The Group believes that a systematic and efficient supply chain not only helps mitigate potential risks arising from supplier operations but also ensures product and service quality that meets customer and stakeholder expectations, while minimizing potential negative impacts. Accordingly, the Group has established its procurement framework in accordance with sustainable procurement practices (ESG), which are implemented across all Group operations in a structured and continuous manner.

The Company’s procurement policy aims for sustainability, fairness, and the best value for money. The Company in particular looks for reasonable pricing in comparison to products or services received from vendors, and price auctioning and vendor selection are regularly done to find the most efficient, ethical vendors per the Supplier Code of Conduct who share our values about the environment, society, and good governance (ESG.)

Selection of business partners that share their vision and business direction with the Company, and ones that subscribe to the Company’s Supplier Code of Conduct, is also paramount. Potential and even already established business partners are regularly asked to undergo an evaluation process that now includes evaluation on their ESG performance and their cost-effectiveness, as well as potential risks the partners may bring with them.

Supply Chain Management and Sustainable Procurement Practices

The Group is committed to promoting and enhancing the capabilities of its suppliers to foster efficient and sustainable growth together. This is achieved through the implementation of the Sustainable Procurement Program, which forms part of the Group’s broader sustainability objectives.

The Company prioritizes partnerships with suppliers who demonstrate environmental awareness and responsibility. It actively supports the use of environmentally friendly products and services, with a focus on sourcing materials and products certified with the Green Label by the Thai Environment Institute (TEI). In addition, the Group encourages the use of alternative fuels, such as biomass, industrial waste, and by-products from manufacturing processes, to reduce reliance on fossil fuels and minimize environmental impact.

Furthermore, the Group continuously promotes supplier participation in the Green Industry Program, particularly encouraging suppliers to maintain at least Level 2 Green Industry certification. The Company plays an active role in providing guidance and collaborating closely on development planning.

Since 2019, more than 37 suppliers, representing a total of 45 manufacturing facilities, have joined the Green Industry Program. This reflects the Group’s strong commitment to elevating environmental standards and advancing long-term sustainability throughout the supply chain.

Occupational Health & Safety

Safety is the priority, hence our strategic mission for the sustainability of the Group

The Board of Directors prioritizes operation safety above all else in the matter of governance. We are acutely aware that that work safety is a critical aspect of human rights that must be ensured in every level of operation and governance, with everyone accountable including supervisors, Executives, and Directors, as well as employees, other stakeholders, and members of the communities surrounding the operation areas.

In 2020, the Board of Directors considered and approved 5 sustainability targets of the Group, which are to be met by 2030. Operation health and safety is one critical matter that is part of such targets. The Board of Directors also approved implementation of key performance indicators (KPI) that reflects this aspiration, including targeting zero harm in all operations across the Group. The Group Chief Executive Officer, who also acts as the Executive Director, is charged by the Board with establishing the Group safety working group, with a senior safety officer acting as the secretary, with roles and responsibilities of the working group clearly defined in its charter. Safety matter is also a standing agenda in the Audit Committee, as part of the Compliance Dashboard reporting, which tracks compliance status across the Group, with the Dashboard being reviewed and submitted to every Group Board of Directors’ meeting. Critical safety incidents are also reported to the Board of Directors, in a Board meeting immediately after one such incident.

To ensure health and safety compliance on all levels, the Group also encourages employee participation in constantly improving the system, with monthly health, safety, and work environment meetings where employee representatives discuss with Management and review the safety situation, as well as brainstorming possible solutions, with minutes of the meetings reported to the Group Executive Committee and the Board of Directors. These discussions are an important mechanism in fostering the culture of safety and participation among all of our employees.

We understand that the safety of contractors is equally important, and work to strategically promote safety among the contractors, including the “Safety Starts with Me” and “Don’t Walk Past” awareness raising campaigns, the Safety Competency campaign, and the INSEE Contractor Safety Management program. Our safety protocols and regulations are also strictly enforced and regularly improved to keep them up to date and appropriate to the current situation.

Our annual review and ranking of risks and critical sustainability matters also indicates that health and safety is of utmost importance both to the Group and to the stakeholders. As such, Management regularly assesses any potential impact of our operation to the public, the environment, and our business performance, and report to the Board of Directors as part of the strategic plan and annual budget which is submitted to the Board of Directors for review and approval. More details on our governance work, under the direction of the Board of Directors and the Committees, can be found on the Company’s website, under “G: Governance” (https://www.siamcitycement.com/th/esg/-g-governance)

Promotion of Safety, Health, and Work Environment

Our employees are the main driving force of our organization, and as such the Group focuses on effective human resource management, which includes effective management of employee benefits and arrangement for suitable work environment, all of which reinforce the efficiency of our business operations and reflect our commitments, as well as positively affect the morale of our employees. To this end, we have established a framework to ensure that safety, health, and environmental international standards are consistently met, and that measures to prevent work-relaited accidents, injuries, and sickness are in place, in addition to fostering a work environment that is conducive of good mental and physical health of all of our employees.

The Group has been certified by international accreditation organizations for our health and safety operation, and we are ever committed to improving our work on these dimensions consistently to exceed international standards be they on the quality, environmental conservation, or operation health and safety fronts. We are committed to proactively prevent any health concerns among our employees through improvement of the work environment, supplying any equipment required for safe and effective safety compliance among our employees.

To promote the culture of safety across the Group, our new employees are required to take part in the safety course, while existing employees, contractors, and relevant parties are annually required to attend a safety review course with 100% attendance being mandatory.

| Training Course | Target Group | ||

|---|---|---|---|

| Employees | Contractors | ||

| Mandatory Course | |||

| 1. Occupational Health, and Safety for New Employees | All new employees | All new contractors | |

| 2. Management-level Occupational Safety Officer Course | All management-level employees | - | |

| 3. Supervisory-level Occupational Safety Officer Course | All supervisory-level employees | - | |

| 4. Occupational and Environmental Diseases | All | - | |

| 5. Occupational Health, Safety and Environment Regulations for Contractors Working in Zone A (Machine operation in high-risk area) | - | All* | |

| 6. Occupational Health, Safety and Environment Regulations for Contractors Working in Zone C (Green area or low-risk area) | - | All* | |

| 7. Basic Fire Fighting | All according to law | - | |

| Occupational Health, and Safety Management System / Risk Based Course | |||

| Health and Safety | 1. Occupational Health, and Safety Management System (INSEE Group) - OHSMS | All | - |

| 2. Defensive Driving Training for 4-wheel vehicle | All new employees* | All new contractors* | |

| 3. Annual Safety Driving Refreshing Course | All* | All* | |

| 4. Occupational Health, Safety and Environment Committee Training Course | All member of Occupational Health, Safety and Environment Committee at plants | - | |

| 5. Occupational Safety in Confined Space (refresh every 5 years) | All* | All* | |

| 6. Crane Operator Safety Training (refresh every 2 years) | All* | All* | |

| 7. First Aid, CPR and AED Training | All* | All* | |

| Emergency | 1. Advance Fire Fighting | All Security and Fire Fighting Team | All Security and Fire Fighting Team |

| 2. Emergency Evacuation and Fire Drill | All | All | |

| 3. Chemical Spill Response | All* | All* | |

| 4. Emergency Evacuation Drill for People Working Near Water | All* | All* | |

*Related to risks of each position

Our Approach to Safety Management

Safety, health, and work environment are critical to all business operations across the Group, and even more so for those involving operation in the plants and mining quarries, as there are higher risks to the lives and health of employees, families of employees, and members of the local communities. This is also directly reflected in our operation and public reputation, which impacts the trust of our clients, and that of the public at large.

The Group is committed to creating an environment for all employees where there is joy in work, allowing our employees to be productive and creative, able to deliver value in a sustainable manner. As such, compliance to the ISO 45001:2018 and the Occupational Health and Safety Act B.E. 2554 is mandatory group-wide, with work emvironment meticulously managed, prioritizing safety in all aspects. We also work to elevate the quality of life of our employees as well as that of their family, and are committed to provide and aid and compensation required in case of the unexpected. The Company designs all workplans with safety risk assessment being a core part of the process. Our process is as outlined below.

- Risk assessment: We assess the severity and likelihood of potential hazards to prioritize risks appropriately. This covers all operation areas and activities, and the assessment is used as part of the workplan to reduce and control safety risks.

- Hazard identification: We collect data relating to possible hazards from equipment, materials, work processes, or the environment and use this data to design safety rules enforced across all employees and contractors.

- Risk control: We design and implement measures to control and eliminate risks as they are identified, as well aws develop safety systems, provide training to supervisors on our safety system, and require regular inspection of equipment and tools before entering work areas.

- Monitoring and review: Control measures are consistently monitored and reported to the safety committee and the Group Executive Committee on a monthly basis, with workplans to reduce the number of incidents to 0 and workplans in case of the unexpected proposed.

The Group has implemented an occupational health and safety management system in accordance with international standards ISO 45001 and/or the national standard TIS 18001:2011 to comprehensively control operational practices. The certification has been granted by accredited independent bodies such as SOCOTECH Certification UK Ltd, Intertek Certification Limited, and the Management System Certification Institute (Thailand). Currently, more than 83 percent of the Group’s subsidiaries and business units have been certified under these standards. The remaining sites are included in the implementation plan to obtain certification, aiming to achieve a unified occupational health and safety management system across the entire Group.

For our business in Thailand, the Saraburi plant has been a consecutive winner of the Zero Accident Campaign, an annual program managed by the Department of Labor Protection and Welfare.

Important Projects

- Digital Transformation: The Group has adopted the use of QR code system for equipment inspection, which helps with efficiency and accuracy, which promotes data-driven decision making in the maintenance planning process, and helps in timely and transparent inspection of equipment and health and safety operation.

- Road Safety: The Group has initiated campaigns to promote road safety for roads in the Group’s premises, to raise awareness of safe and responsible driving for our employees during or outside of work hours.

- Collaborative safety: The Company conducts regular inter-organizational audits and promotes peer support to help drive our culture of improvement, and encourage mutual learning among Group Companies.

- Mental and physical health of employees: The Group sees the importance of health, quality of life, and safety of all stakeholders, including all of our employees, contractors, and members of the surrounding communities, as well as our business allies. We have initiated various health promotion activities, such as the INSEE We’re Strong program, which promotes the well-being of mental and physical health to reduce risks of non-communicable diseases such as diabetes, heart disease, and cancer, and communicable diseases such as flu, tuberculosis, hepatitis, and COVID-19. In addition, the Company has also initiated various health promotion activities and provide health and financial knowledge to our employees and members of the communities.

Human Rights & Community

Along the value chain, SCCC Group identifies the groups of stakeholders to ensure the effectiveness of our business operations by placing high value on information, suggestions and recommendations from key stakeholders. We analyze obtained information to formulate our engagement strategy to meet the requirements and expectations of stakeholders.

The company provided the Human Resources Policy is established to provide an overall framework and guiding principles with regards to Human Resources related processes and consistent practices across Group company. The Group aims to be a well-recognized employer in the construction and building material industry by creating competitive employment propositions, attracting, and retaining a high performing and diverse workforce, facilitating continual learning and personal growth while embedding a strong performance-driven culture and values into our working DNA.

The policy stipulates that the Head of Group Company HR (GC-HR) is responsible for implementing, maintaining and developing related HR processes and practices in line with this Human Resources Policy of the Group company.

Corporate Governance

Siam City Cement Public Company Limited (SCCC) recognizes the value of good governance and remains firmly committed to implementing and practicing good Corporate Governance (CG) across all its operations in pursuit of long term sustainable growth, adding value to all stakeholders.

The Board of Directors has prepared the Corporate Governance Policy as guidelines for the entire Group by adopting both principles and guidelines on Corporate Governance Code for Listed Companies 2017 of the Securities and Exchange Commission, Thailand (SEC). In particular, the Board of Directors delegated to the Governance Committee to conduct an annual review on the conformation of the Company’s corporate governance implementation with CG principles and guidelines of multiple governance bodies, such as the SEC, Thai Institute of Directors, and Thai Investors Association. The Governance Committee discussed and ensure that no issue that has impact on the Company’s corporate governance, and the Company has continuously improved the practices in governance and report the progress to the Board of Directors.

Policy on Remunerations of Executive Directors and Executives

The NCC is charged with designing an Executive compensation scheme that is fair, proportionate to an Executive’s role and responsibilities, and in alignment with the objectives, goals, performance, and long-term interests of the Group, with consideration towards compensation schemes by industrial peers and businesses in adjacent industries for reference.

The NCC is of the opinion that the current compensation scheme is sufficiently incentivizing and competitive relative to industrial standards, with the compensation package including salary, short-term bonus, and a long-term incentive (LTI) paid periodically over three years as performance targets are met. The LTI scheme is applied to all members of the Group Executive Committee (GEXCO) to ensure alignment between executive performance and the Group’s sustainable value creation objectives.

LTI is a crucial mechanism for fostering sustainable growth, promoting Executives to build long-term value for the Company, and driving the Company in a manner that is aligned with the interests of the Shareholders.